Polyacrylamide

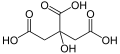

Polyacrylamide (IUPAC poly(2-propenamide) or poly(1-carbamoylethylene), abbreviated as PAM) is a polymer (-CH2CHCONH2-) formed from acrylamide subunits. It can be synthesized as a simple linear-chain structure or cross-linked, typically using N,N '-methylenebisacrylamide. In the cross-linked form, the possibility of the monomer being present is reduced even further. It is highly water-absorbent, forming a soft gel when hydrated, used in such applications as polyacrylamide gel electrophoresis and in manufacturing soft contact lenses. In the straight-chain form, it is also used as a thickener and suspending agent. More recently, it has been used as a subdermal filler for aesthetic facial surgery (see Aquamid).

1 - Uses of polyacrylamide

One of the largest uses for polyacrylamide is to flocculate solids in a liquid. This process applies to water treatment, and processes like paper making, Screen Printing. Polyacrylamide can be supplied in a powder or liquid form, with the liquid form being subcategorized as solution and emulsion polymer. Even though these products are often called 'polyacrylamide', many are actually copolymers of acrylamide and one or more other chemical species, such as an acrylic acid or a salt thereof. The main consequence of this is to give the 'modified' polymer a particular ionic character.

Another common use of polyacrylamide and its derivatives is in subsurface applications such as Enhanced Oil Recovery. High viscosity aqueous solutions can be generated with low concentrations of polyacrylamide polymers, and these can be injected to improve the economics of conventional waterflooding.

It has also been advertised as a soil conditioner called Krilium by Monsanto Company in the 1950s and today "MP", which is stated to be a "unique formulation of PAM (water-soluble polyacrylamide)". It is often used for horticultural and agricultural use under trade names such as Broadleaf P4, Swell-Gel and so on. The anionic form of cross-linked polyacrylamide is frequently used as a soil conditioner on farm land and construction sites for erosion control, in order to protect the water quality of nearby rivers and streams.

The polymer is also used to make Gro-Beast toys, which expand when placed in water, such as the Test Tube Aliens. Similarly, the absorbent properties of one of its copolymers can be utilized as an additive in body-powder.

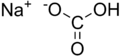

The ionic form of polyacrylamide has found an important role in the potable water treatment industry. Trivalent metal salts like ferric chloride and aluminium chloride are bridged by the long polymer chains of polyacrylamide. This results in significant enhancement of the flocculation rate. This allows water treatment plants to greatly improve the removal of total organic content (TOC) from raw water.

Polyacrylamide is often used in molecular biology applications as a medium for electrophoresis of proteins and nucleic acids in a technique known as PAGE.

It was also used in the synthesis of the first Boger fluid.

- Soil Conditioner

The primary functions of Polyacrylamide Soil Conditioners are to increase soil tilth, aeration, and porosity and reduce compaction, dustiness and water run-off. Secondary functions are to increase plant vigor, color, appearance, rooting depth and emergence of seeds while decreasing water requirements, diseases, erosion and maintenance expenses. FC 2712 is used for this purpose.

2 - Stability

In dilute aqueous solution, such as is commonly used for Enhanced Oil Recovery applications, polyacrylamide polymers are susceptible to chemical, thermal, and mechanical degradation. Chemical degradation occurs when the labile amine moiety hydrolyzes at elevated temperature or pH, resulting in the evolution of ammonia and a remaining carboxyl group. Thus, the degree of anionicity of the molecule increases. Thermal degradation of the vinyl backbone can occur through several possible radical mechanisms, including the autooxidation of small amounts of iron and reactions between oxygen and residual impurities from polymerization at elevated temperature. Mechanical degradation can also be an issue at the high shear rates experienced in the near-wellbore region. However, cross-linked variants of polyacrylamide have shown greater resistance to all of these methods of degradation, and have proved much more stable.

3 - Environmental effects

Concerns have been raised that polyacrylamide used in agriculture may contaminate food with acrylamide, a known neurotoxin. While polyacrylamide itself is relatively non-toxic, it is known that commercially available polyacrylamide contains minute residual amounts of acrylamide remaining from its production, usually less than 0.05% w/w.

Additionally, there are concerns that polyacrylamide may de-polymerise to form acrylamide. In a study conducted in 2003 at the Central Science Laboratory in Sand Hutton, England, polyacrylamide was treated similarly as food during cooking. It was shown that these conditions do not cause polyacrylamide to de-polymerise significantly.

In a study conducted in 1997 at Kansas State University, the effect of environmental conditions on polyacrylamide were tested, and it was shown that degradation of polyacrylamide under certain conditions can cause the release of acrylamide. The experimental design of this study as well as its results and their interpretation have been questioned, and a 1999 study by the Nalco Chemical Company did not replicate the results.

One of the largest uses for polyacrylamide is to flocculate solids in a liquid. This process applies to water treatment, and processes like paper making, Screen Printing. Polyacrylamide can be supplied in a powder or liquid form, with the liquid form being subcategorized as solution and emulsion polymer. Even though these products are often called 'polyacrylamide', many are actually copolymers of acrylamide and one or more other chemical species, such as an acrylic acid or a salt thereof. The main consequence of this is to give the 'modified' polymer a particular ionic character.

Another common use of polyacrylamide and its derivatives is in subsurface applications such as Enhanced Oil Recovery. High viscosity aqueous solutions can be generated with low concentrations of polyacrylamide polymers, and these can be injected to improve the economics of conventional waterflooding.

It has also been advertised as a soil conditioner called Krilium by Monsanto Company in the 1950s and today "MP", which is stated to be a "unique formulation of PAM (water-soluble polyacrylamide)". It is often used for horticultural and agricultural use under trade names such as Broadleaf P4, Swell-Gel and so on. The anionic form of cross-linked polyacrylamide is frequently used as a soil conditioner on farm land and construction sites for erosion control, in order to protect the water quality of nearby rivers and streams.

The polymer is also used to make Gro-Beast toys, which expand when placed in water, such as the Test Tube Aliens. Similarly, the absorbent properties of one of its copolymers can be utilized as an additive in body-powder.

The ionic form of polyacrylamide has found an important role in the potable water treatment industry. Trivalent metal salts like ferric chloride and aluminium chloride are bridged by the long polymer chains of polyacrylamide. This results in significant enhancement of the flocculation rate. This allows water treatment plants to greatly improve the removal of total organic content (TOC) from raw water.

Polyacrylamide is often used in molecular biology applications as a medium for electrophoresis of proteins and nucleic acids in a technique known as PAGE.

It was also used in the synthesis of the first Boger fluid.

- Soil Conditioner

The primary functions of Polyacrylamide Soil Conditioners are to increase soil tilth, aeration, and porosity and reduce compaction, dustiness and water run-off. Secondary functions are to increase plant vigor, color, appearance, rooting depth and emergence of seeds while decreasing water requirements, diseases, erosion and maintenance expenses. FC 2712 is used for this purpose.

2 - Stability

In dilute aqueous solution, such as is commonly used for Enhanced Oil Recovery applications, polyacrylamide polymers are susceptible to chemical, thermal, and mechanical degradation. Chemical degradation occurs when the labile amine moiety hydrolyzes at elevated temperature or pH, resulting in the evolution of ammonia and a remaining carboxyl group. Thus, the degree of anionicity of the molecule increases. Thermal degradation of the vinyl backbone can occur through several possible radical mechanisms, including the autooxidation of small amounts of iron and reactions between oxygen and residual impurities from polymerization at elevated temperature. Mechanical degradation can also be an issue at the high shear rates experienced in the near-wellbore region. However, cross-linked variants of polyacrylamide have shown greater resistance to all of these methods of degradation, and have proved much more stable.

3 - Environmental effects

Concerns have been raised that polyacrylamide used in agriculture may contaminate food with acrylamide, a known neurotoxin. While polyacrylamide itself is relatively non-toxic, it is known that commercially available polyacrylamide contains minute residual amounts of acrylamide remaining from its production, usually less than 0.05% w/w.

Additionally, there are concerns that polyacrylamide may de-polymerise to form acrylamide. In a study conducted in 2003 at the Central Science Laboratory in Sand Hutton, England, polyacrylamide was treated similarly as food during cooking. It was shown that these conditions do not cause polyacrylamide to de-polymerise significantly.

In a study conducted in 1997 at Kansas State University, the effect of environmental conditions on polyacrylamide were tested, and it was shown that degradation of polyacrylamide under certain conditions can cause the release of acrylamide. The experimental design of this study as well as its results and their interpretation have been questioned, and a 1999 study by the Nalco Chemical Company did not replicate the results.

Wikipedia.org